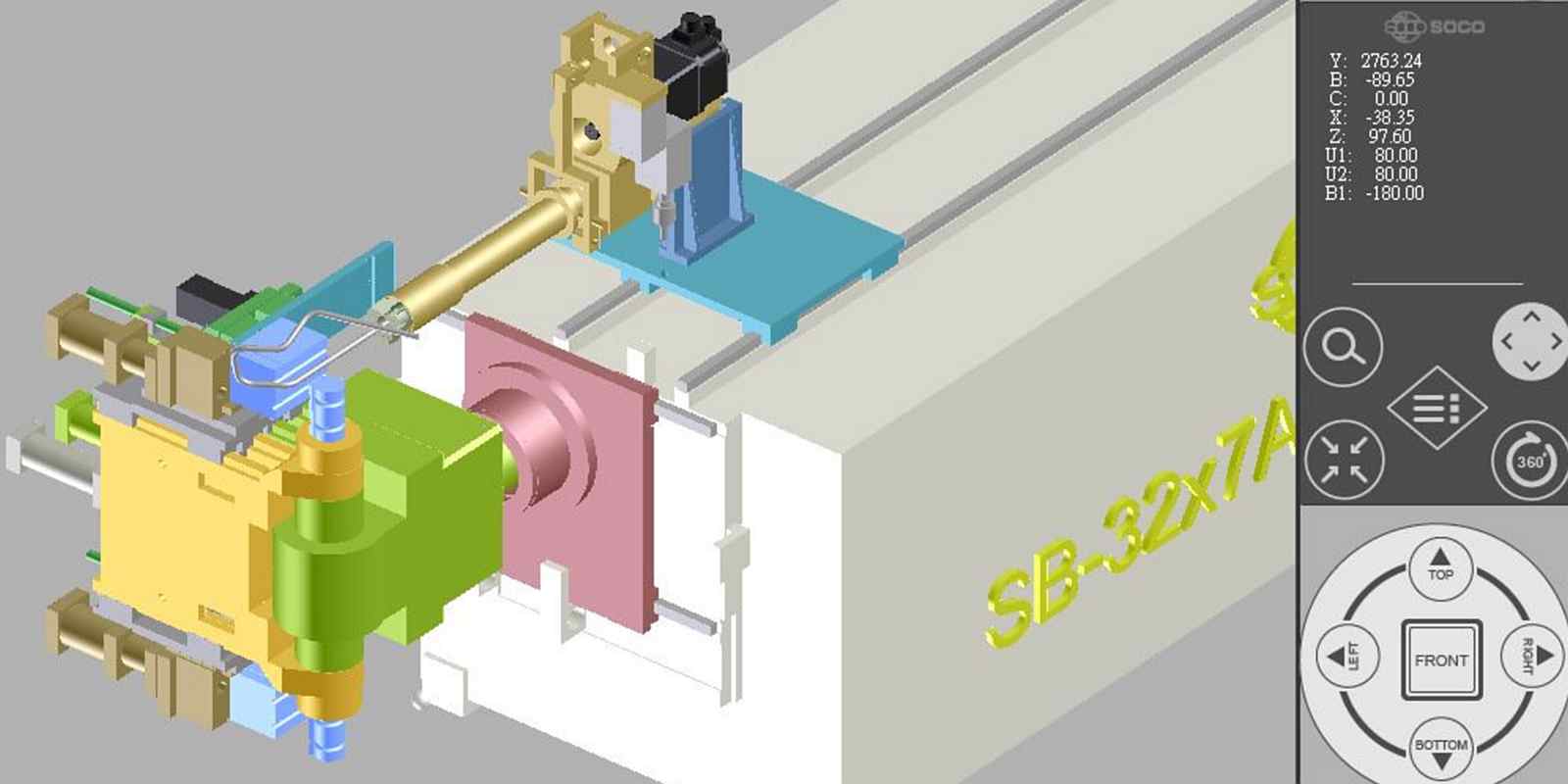

SOCO’s i2 ® CNC Controls: Tube Benders

The Most Powerful + User Friendly

Tube Bender Software in the World

SOCO’s i2 CNC Controls is the most advanced and intuitive software in the tube bending industry. It offers an unparalleled platform for factory management, output production and parts development, as well as integration to measuring, automation and other SOCO manufacturing solutions.

(*) On select machine models

(+) Optional

The Most Powerful + User Friendly

Tube Bender Software in the World

SOCO’s i2 CNC Controls is the most advanced and intuitive software in the tube bending industry. It offers an unparalleled platform for factory management, output production and parts development, as well as integration to measuring, automation and other SOCO manufacturing solutions.

(*) On select machine models

(+) Optional

FOR THE OPERATOR AND PRODUCTION

- Windows Based system with Graphic Intuitive Interface and Map Navigation to all screens.

- Automatic Springback Compensation + Recapture for Short Lengths.

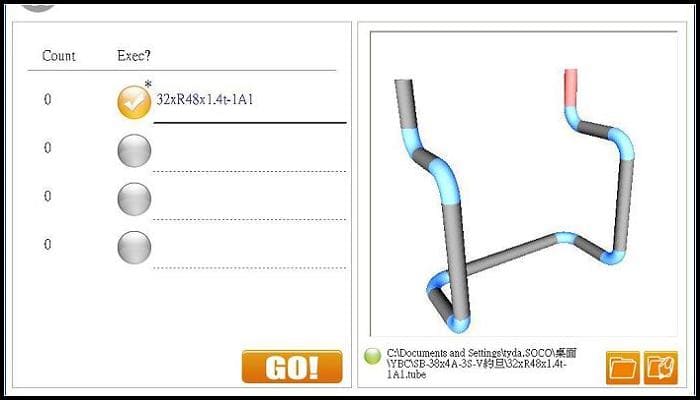

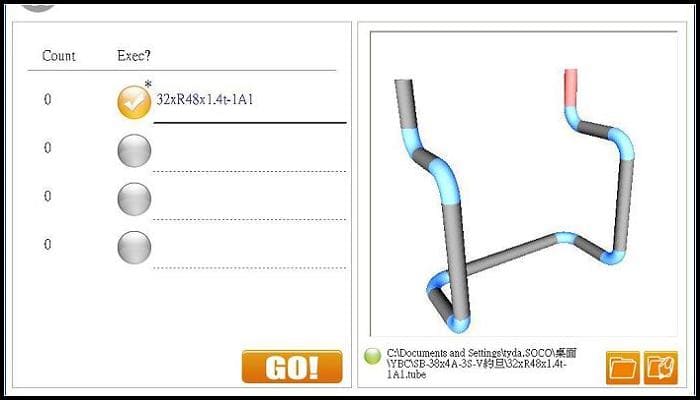

- Simultaneous running of multiple bending files for producing complete product sets.

- PDI Zone Recapture : Carriage moves into the PDI Zone for completion of short length bends with minimal material waste.

- 「Overmode / Teach Mode」 offers easy setup of each programmable axis to avoid interferences between bends.

- Action Sequences: Multiple built-in sequences for automatic offset moves between bends.

FOR R&D + PARTS DESIGN

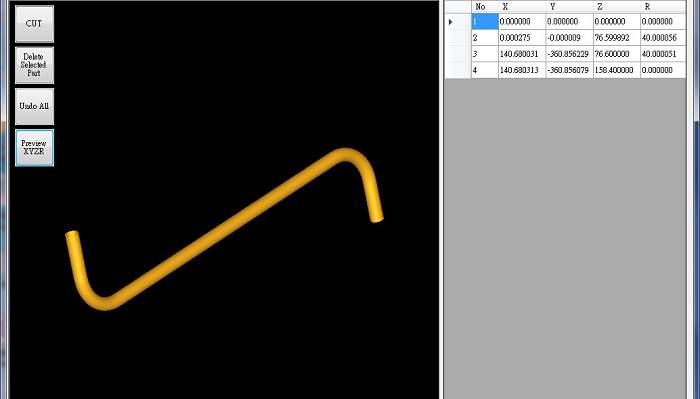

- 3-Step Programming allows the creation of a new part from scratch in minutes.

- SOCO CAD Reader (+): Ability to open 3D CAD files (.step) and automatically fill in coordinates and tube data.

- SOCO Bending Simulator (+): Bending Simulation and Collision Detection software.

- CMM Interface (+): Ability to connect to AICON / CMM measuring systems for automatic parts compensation and reverse engineering.

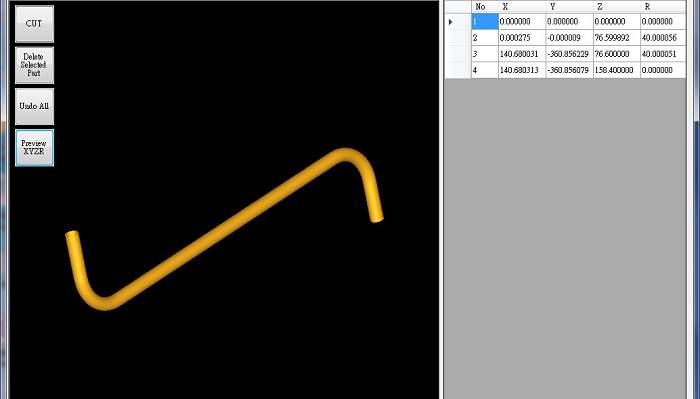

- Data entry for both XYZ and YBC coordinates and XYZ <-> YBC conversion.

- Dedicated Carriage + PDA Booster and Torque Setting page.

- SOCO VRM: Arc Radius Measuring for quick setup of large radius parts.

- Offline i2 Controls for development, simulation, and data analysis in an office setting.

FOR SERVICE AND MAINTENANCE

- SOCO IRMS: Live Support and trouble shooting from Anywhere, Anytime

- Connect using any mobile device, computer, or laptop (Windows, iOS, or Android) from any locationwith Internet access

- On-Screen access to bending files, with full ability to read, edit, and troubleshoot programmed parts

- Self-diagnostics : Error message display with potential solutions

- Machine Maintenance Scheduling System (+).

FOR MANAGEMENT

- SOCO’s Production Reports : Generate complete production reports by time frame, machine, and operator

- Ability to Connect to Internal Data Backup and 3rd Party Cloud Storage Systems

- Tooling Management System : Independent tool library and Tooling life tracking

- User Permissions Control : 3 security levels + ability to create over 1,000 user IDs

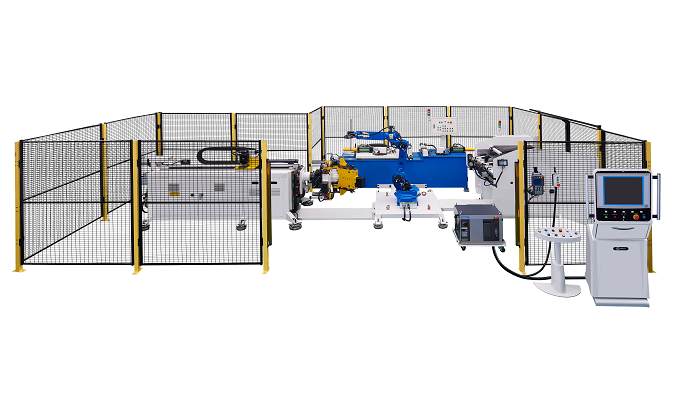

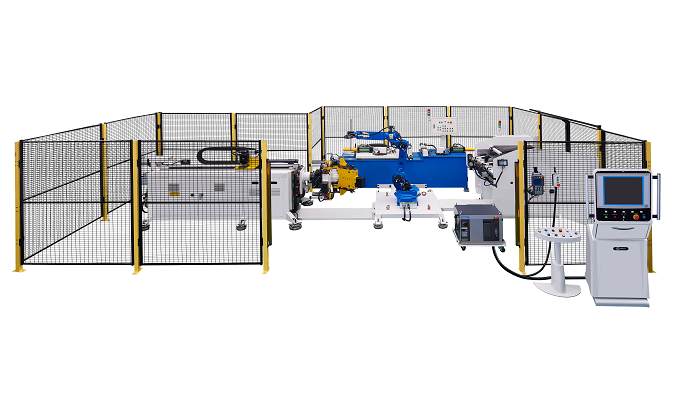

FOR AUTOMATION (+)

• SOCO i2 Automation Modules Offer Complete Access to Turn-Key Solutions, such as:

(1) Robotic Loading Systems.

(2) SOCO Dedicated Loading + Unloading Systems.

(3) Transfer Modules for Other Products such as:

- SOCO SLT Tube Lasers

- SOCO Tube Saw Cutting/2C Shearing.

- Tube End Finishing/End Forming/Washing/Laser Marking.

• Ability to connect CMM Systems for Data Compensation.

• Ability to connect to MES/ERP Data Sharing Platforms.