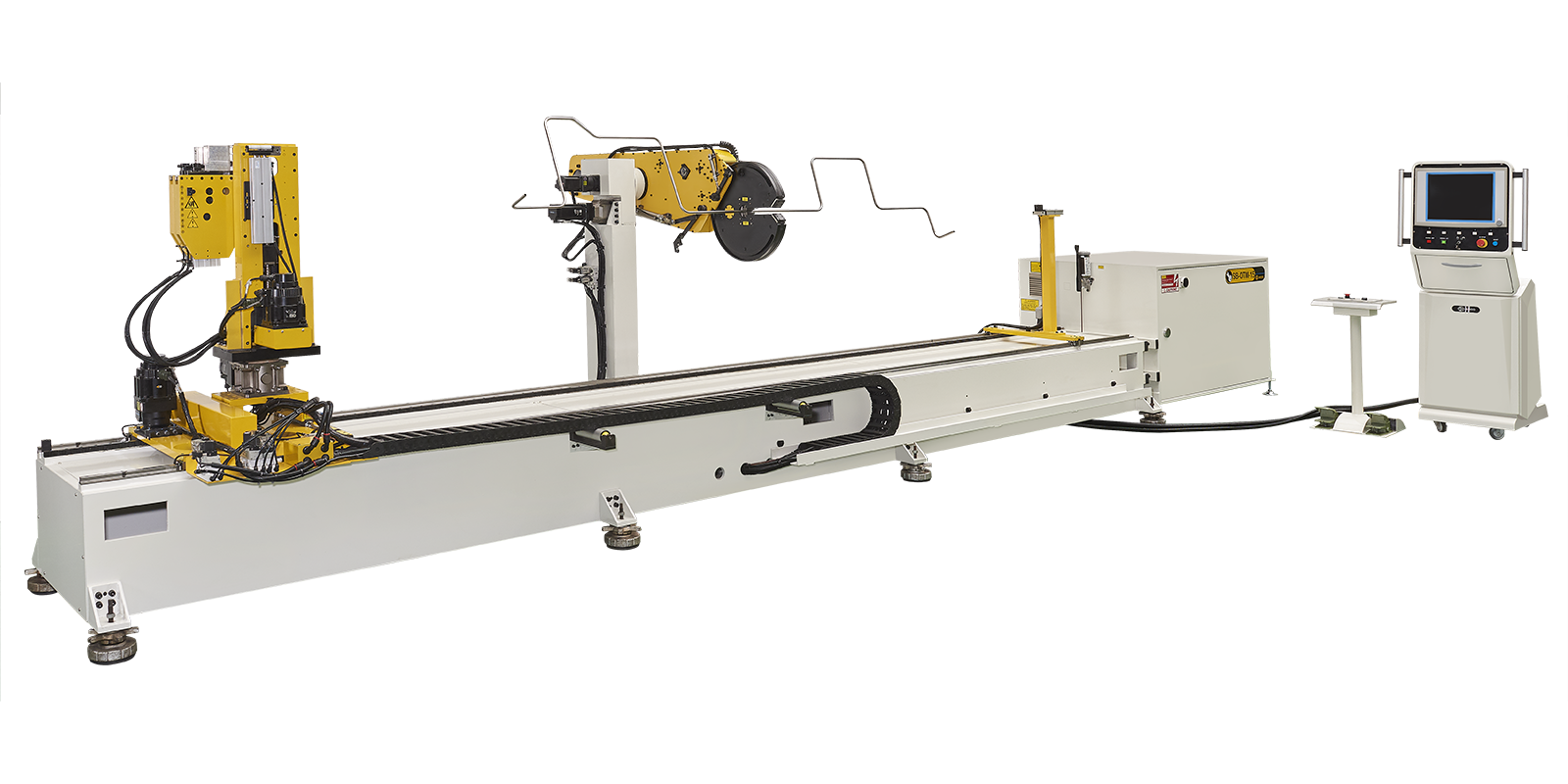

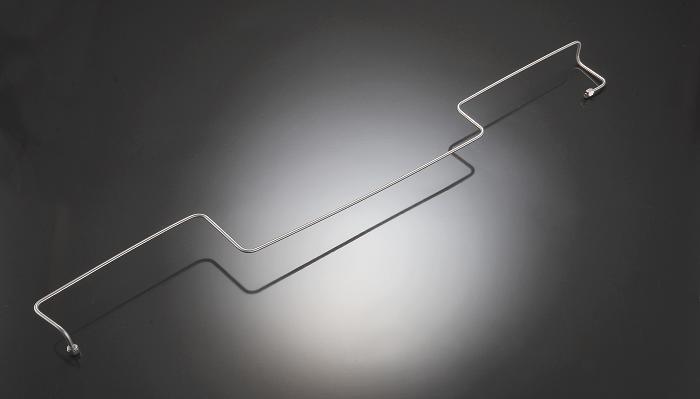

3 ~ 8 Electric Axis Tube Benders for Vehicle Brake Line

Tube Length capacity up to 5000 mm

The SOCO SB-Oil Tube Master is a dedicated CNC Brake Line Tube Benders. Designed for small tubing, especially Bundy Tubes and Hydraulic Lines. With multiple electric axes and a unique design to allow bending complex shapes and parts. It offers the most advanced solution and performance in its range.

Suitable for Brake Line tubing up to 4000 mm ~5000 mm and unparalleled Pipe Bending Speed. This CNC Pipe Bending Machines with optional Automatic Loading and Unloading Interface.

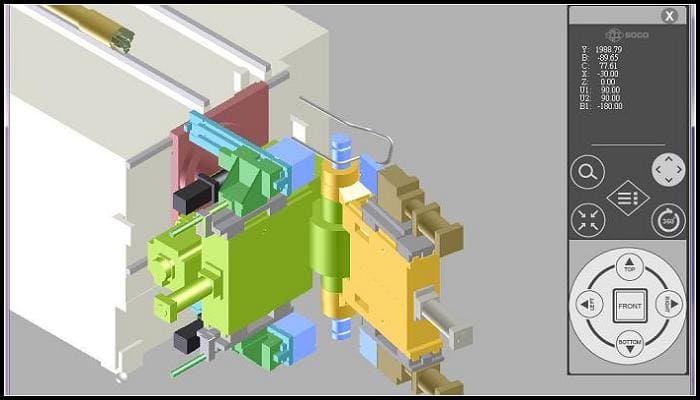

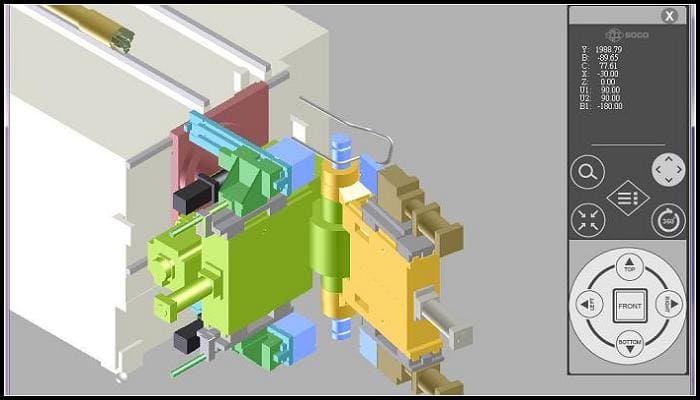

Maximum Working Area = Minimal Interference:

Software

Tube Length capacity up to 5000 mm

The SOCO SB-Oil Tube Master is a dedicated CNC Brake Line Tube Benders. Designed for small tubing, especially Bundy Tubes and Hydraulic Lines. With multiple electric axes and a unique design to allow bending complex shapes and parts. It offers the most advanced solution and performance in its range.

Suitable for Brake Line tubing up to 4000 mm ~5000 mm and unparalleled Pipe Bending Speed. This CNC Pipe Bending Machines with optional Automatic Loading and Unloading Interface.

- SB-Oil Tube Master , 3 Electric Axis Tube Benders, Max. capacity is OD 8 x 4000 mm

- SB-OTM-15, 8 Electric Axis Tube Benders, Max. capacity is OD 15 x 5000 mm

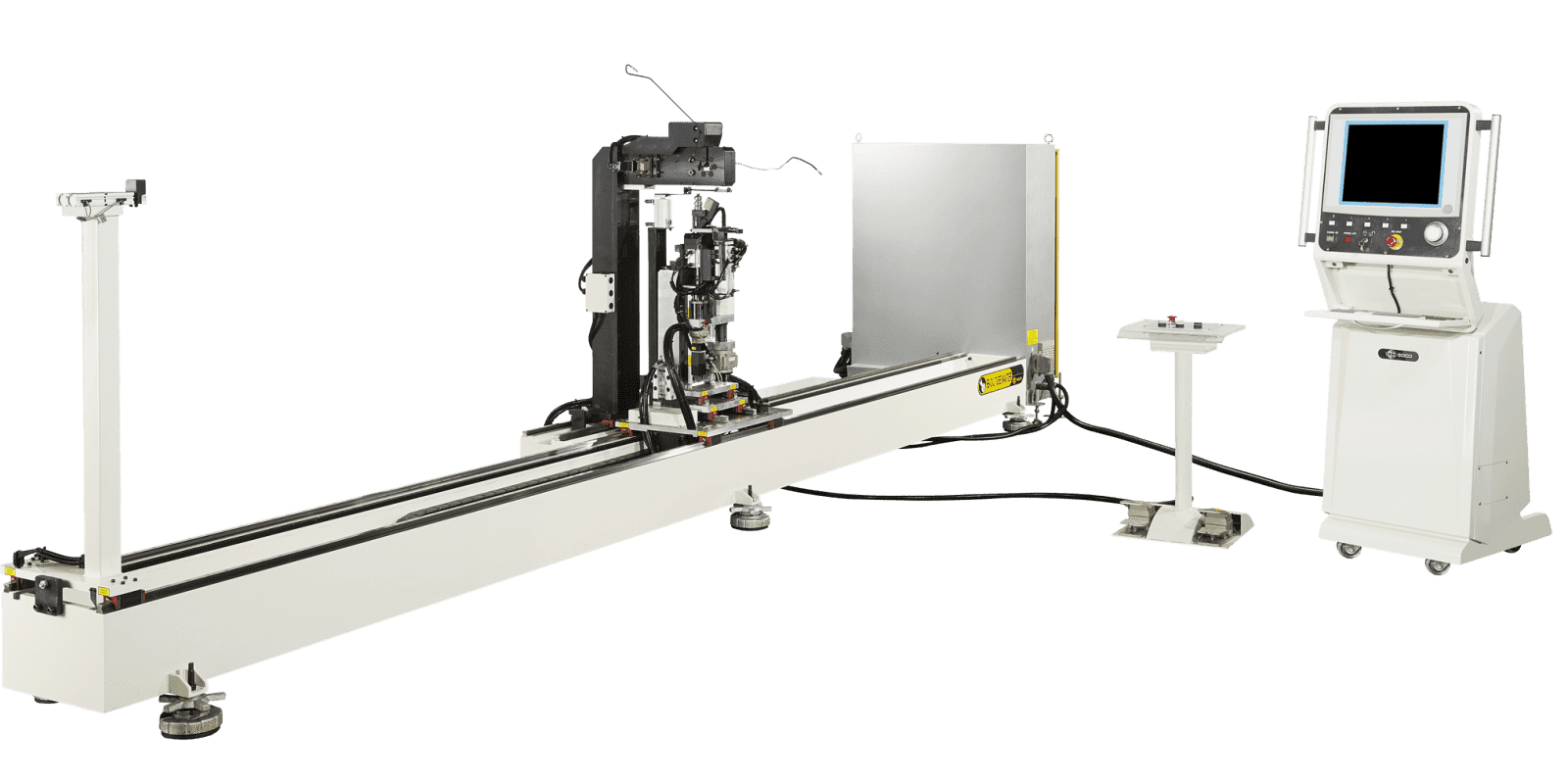

Maximum Working Area = Minimal Interference:

- No interference with the machine bed

- No conventional bending arm

- No pressure die and wiper die seat interferences

- Central clamping and rotation away from bending zone

- Overmode (Arm Return Mode) capabilities

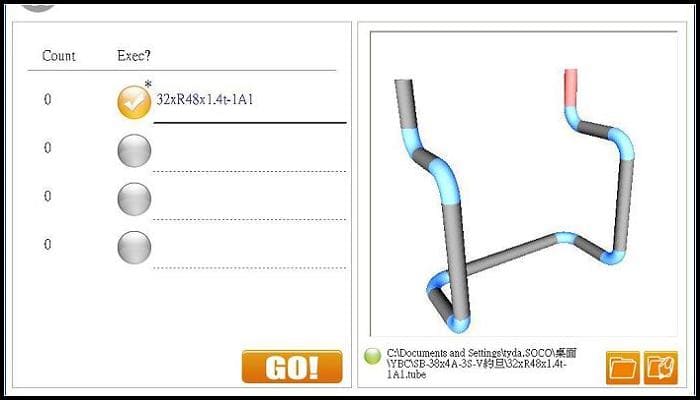

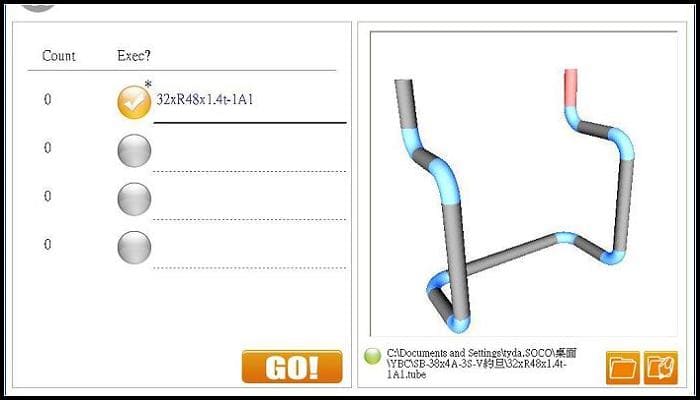

Software

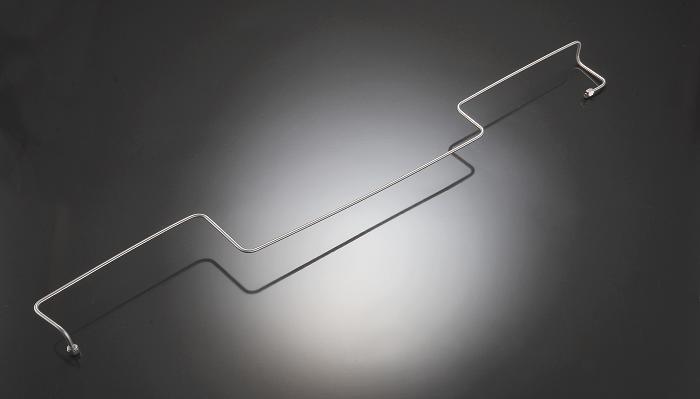

- May program up to 50 bends per part, with on-screen 3D part display

- Data entry for both XYZ and YBC coordinates

- Overmode (Arm Return Mode) offers flexibility to offset each bend and avoid bending interferences.

- Integrated Automatic Bending Compensation and Reverse Engineering of bends when connected to CMM Measuring systems

- Connection to Local Area Network (LAN) (Optional)

Automation Tube Bending Machine

- 3 ~ 8 Electric-Axis controlling tube bending, tube rotation, and carriage movement

- Automatic bending head reversal (left to right) when reaching the central clamping area, providing a fully automatic cycle for the entire bending process

- Optional Automatic Loading and Unloading Interface

Suitable for brake line tubing up to 5000 mm

- Centralized clamping and rotation system for true simultaneous moving of all axis

- Lowest cycle times because minimal number of moving parts

- Suitable for brake line tubing up to 4000 mm ~ 5000 mm.

SOCO i2 Controls, Tube Bending Software and Operation Interface

- Automatic springback compensation

- Recapturing function for short lengths

- XYZ and YBC coordinates conversion

- 3D display and rotation of bending parts

- Mirroring and image reversal of parts

- Windows platform

- Self-diagnostics + Error messages display

- Connection and auto tube bending compensation to CMM systems

- Overmode + Teach Mode

- Live remote monitoring by internet

- Remote troubleshooting

- Connection through PC, Mobile Phone and Tablet

- Tube bending interference and collision simulator

- SOCO CAD Reader

- VRM: Variable Radius Measuring System

SOCO IRMS (Internet Remote Monitoring System)

- Customizable Alarms for Daily, Weekly, Quarterly, and Yearly Items;

- Maintenance Records connected to User Login.

- True Remote Access from Anywhere: Connect to i2 Controls using any mobile device, computer, or laptop (Windows, iOS, or Android) from any location with Internet Access.

- Actual Screen + Real-Time Access to tube bending file, with full ability to see, edit and troubleshoot all user-created programs.

- Live Remote Connection to Manufacturer and Service Support with Ability to Call + Message + Record at the same time.

- Maintenance Scheduling Systems:

- Customizable Alarms for Daily, Weekly, Quarterly, and Yearly Items;

- Maintenance Records connected to User Login.

- Built-in Self-diagnostics + Error messages display + I/O Tables with Descriptions.

- Webcam Ready for Video Monitoring (Optional).

3D Display and Rotation of Tube Bending Parts

- XYZ and YBC coordinates conversion

- Mirroring and image reversal of parts