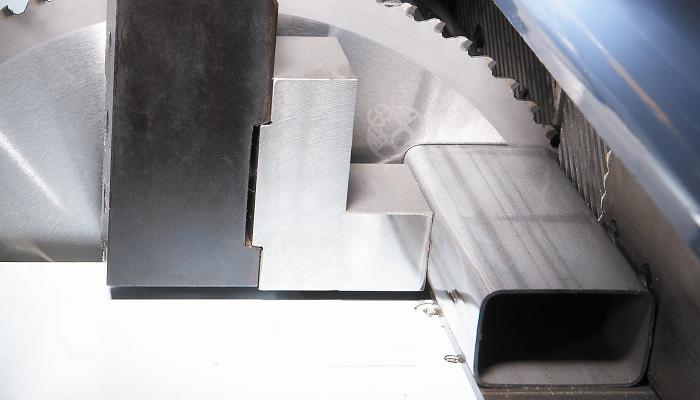

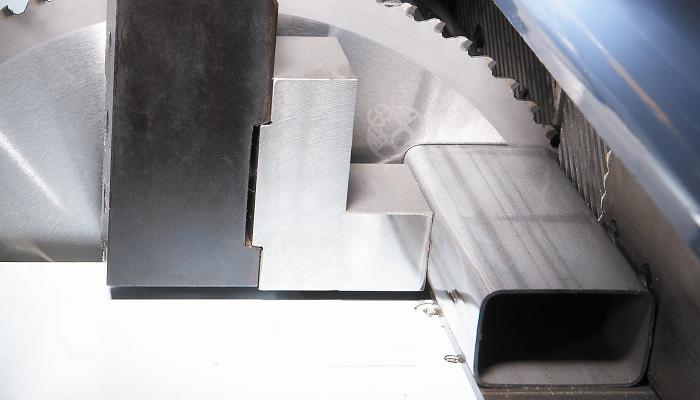

High Tensile Steel Tube Cutting by TCT Saw Blade

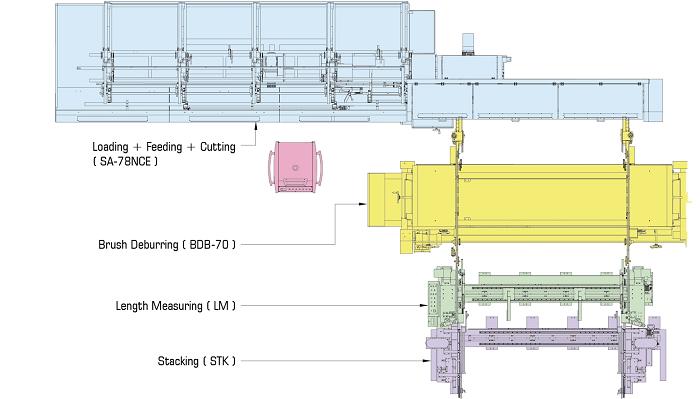

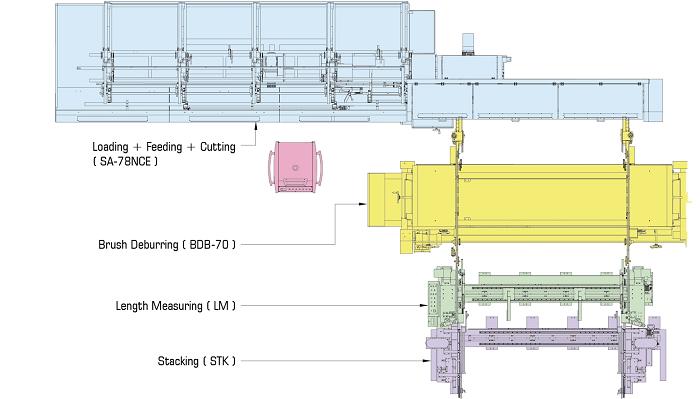

Tube Cutting + Deburring/Chamfering + Length Measuring + Stacking

High Tensile Steel

The High Tensile Steel Tube is now widely applied in the global automotive market. In order to achieve higher fuel efficiency and lowering materials costs, thicker tubes and solid bars have been replaced by thin wall High Tensile tubes, which achieve lower weight without compromising strength and safety. With a much higher tensile strength (80 -120 Kg/cm²) than conventional steels (40 - 50 Kg/cm²), this material is highly employed in key areas of cars for structural applications (chassis) and impact protection.

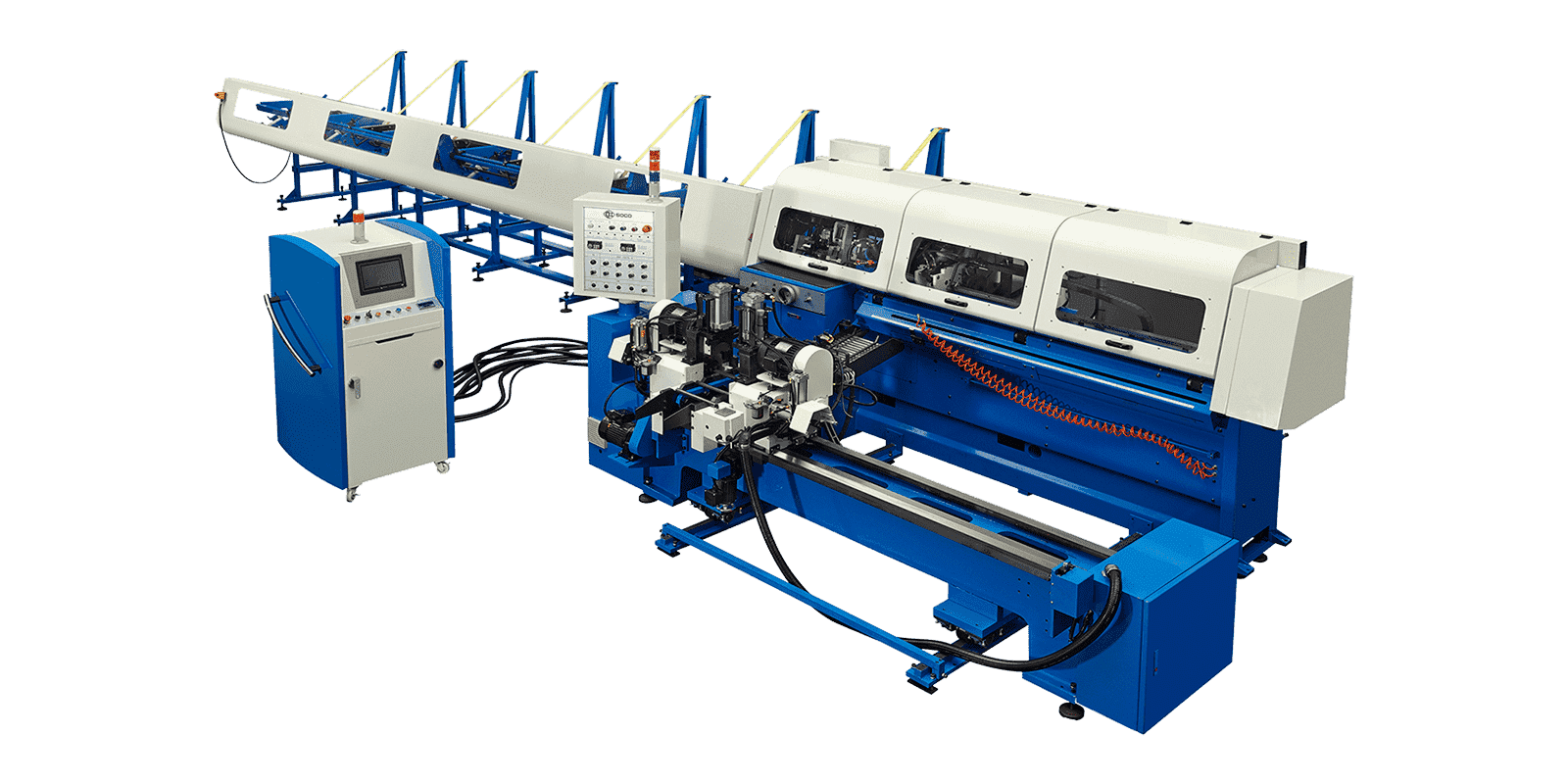

The new SOCO SA-78NCE tube cutting line brings you the latest technology in High Tensile Steel Tube Sawing. Its unique design and cutting system bring the highest saw blade life in such applications, as well as unparalleled performance and speed.

Machine Features:

This Tube Cutting machine is capable of sawing various shapes of profiles such as round, rectangular, square tubes, and round bars. As part of automation cells, It may be connected to :

Tube Cutting + Deburring/Chamfering + Length Measuring + Stacking

High Tensile Steel

The High Tensile Steel Tube is now widely applied in the global automotive market. In order to achieve higher fuel efficiency and lowering materials costs, thicker tubes and solid bars have been replaced by thin wall High Tensile tubes, which achieve lower weight without compromising strength and safety. With a much higher tensile strength (80 -120 Kg/cm²) than conventional steels (40 - 50 Kg/cm²), this material is highly employed in key areas of cars for structural applications (chassis) and impact protection.

The new SOCO SA-78NCE tube cutting line brings you the latest technology in High Tensile Steel Tube Sawing. Its unique design and cutting system bring the highest saw blade life in such applications, as well as unparalleled performance and speed.

Machine Features:

- Especially suitable for Cutting Automotive parts such as Impact Beams, Chassis, and Cross Bar tubing

- Standard with 6.5 meters Bundle Loading Magazine (MB6), optional 8.5 meters (MB8) and 12.5 meters (MB12)

- Automatic separation of first and last cut vs. working pieces

- First and crop cuts down to 25 mm

- Quick Saw Blade Change system

- Safety covers for operational safety and minimizing noise levels

- 1 or 2 optional length stoppers with Digital Length Readout. NC Length Stopper is available if requested

- 2 Loading Positions available: Left Side and Right Side Loading Magazines

- Electric Servo Controlled Feeding and Cutting

- i2® Touch Screen Graphical Controls with Automatic Recommendation of Cutting Parameters. 3 to 5 minutes setup time between most tube sizes

- Unique Blade Holders and Gearbox Brake System for complete backlash elimination

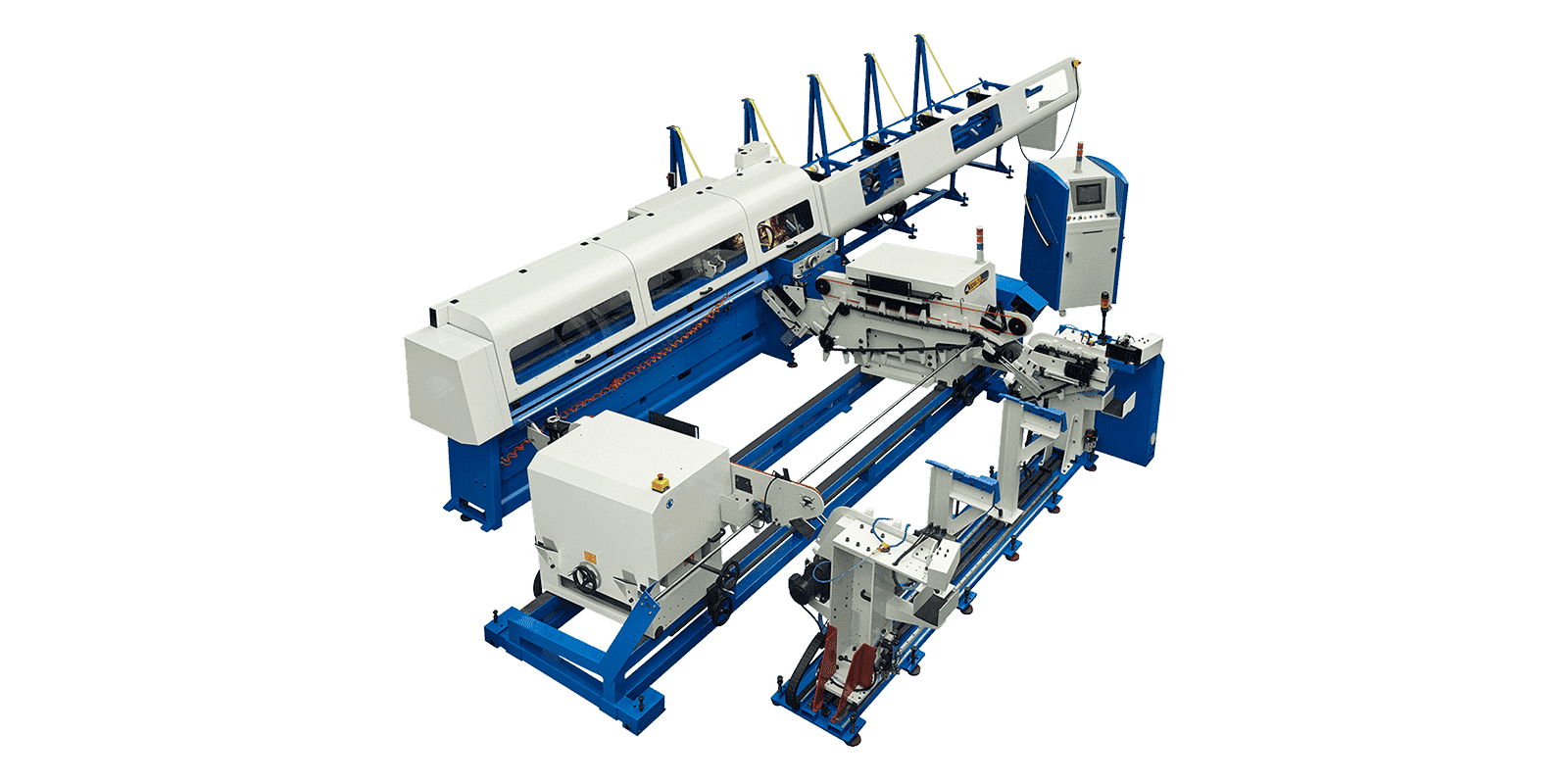

- May connected to SOCO's Tube Deburring Machine (BDB-70) or Tube Chamfering Machine (FM-76V), Length Measuring (LM-3000), and Stacking (STK-3000)

This Tube Cutting machine is capable of sawing various shapes of profiles such as round, rectangular, square tubes, and round bars. As part of automation cells, It may be connected to :

- Brush Deburring (BDB-70) or Chamfering (FM-76V)

- Length Measuring (LM-3000)

- Stacking (STK-3000)

Especially suitable for Cutting Automotive parts such as Impact Beams, Chassis and Cross Bar tubing

- Capacity up to OD 78 mm tubing. Sawing Lengths up to 2 - 4.5 meters

- High Tensile Tube Cutting (up to 120 kg/cm²)

- TCT Saw Blades are recommend

- High-Speed Sawing: the average sawing cycle times can be up to 4.5 seconds for most sizes.

Tube Cutting + Deburring or Chamfering + Length Measuring + Stacking

Length Measuring - LM-3000

Stacking – STK-3000

Length Measuring - LM-3000

- Length Measuring System with Programmable Interface and Touch Screen

- Length measuring tolerances of +/- 0.01mm.

- Motorized measuring length adjustment.

- Automatic separation against rejected parts

- Automatic Stoppage when rejected parts reach a set quantity

Stacking – STK-3000

- Suitable for Round Tubes and Profiles

- Standard with Safety System for Unloading of finished parts without production stoppage

1 or 2 optional length stoppers with Digital Length Readout. NC Length Stopper is available in optional

Standard with 6.5 meters Bundle Loading Magazine ( MB6 ), optional 8.5 meters ( MB8 ) and 12.5 meters ( MB12 )

- Standard with 6.5 m Bundle Loading Magazine (MB6), optional 8.5 m (MB8), and 12.5 m (MB12)

- Automatic separation of first and last cut vs. working pieces

- Safety covers for operational safety and minimizing noise levels

- 2 Loading Positions available: Left Side and Right Side Loading Magazines