How Does SOCO Overcome Difficulties?

Media 2020/10/15

SOCO has a strategy to attract engineers that have experience at TSMC. Paying the personnel 20% more than the others in the industry, offering welfare plans that can help employees improve their quality of life in the medium and long term, combined with the advantages of a friendly work environment. Several engineers of different specializations joined SOCO: software engineers, assembling engineers, electromechanical, information and communications, big data, and laser applications engineers. The R&D department has grown from 20 people to about 50 people in 5 years.

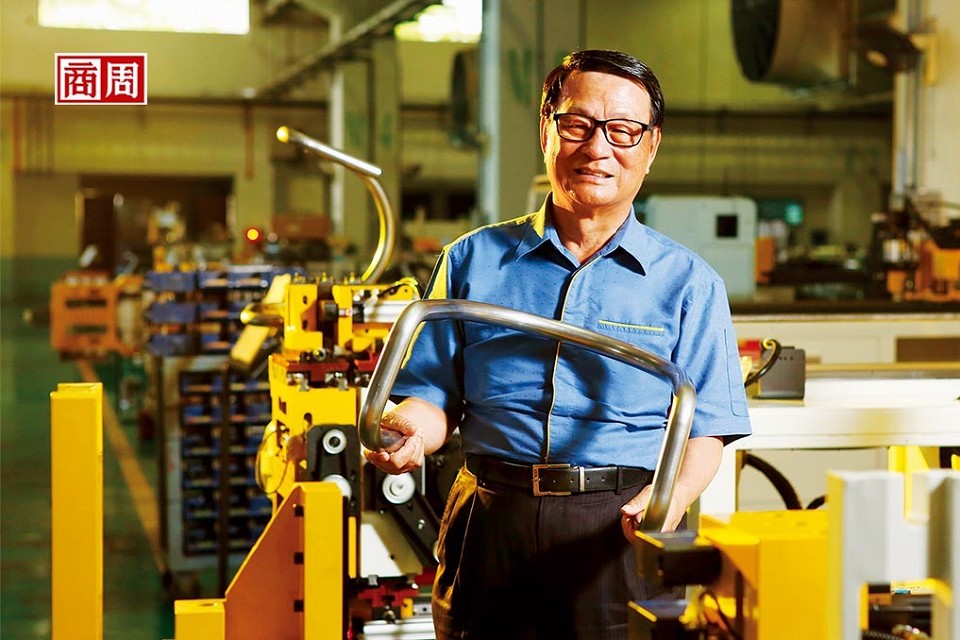

"For a company to be competitive, it must be able to attract good talents." Frank Lin firmly believes. This allows SOCO Machinery's R&D personnel to account for about 20% of the total number of employees, a higher number compared to the machine tool stock king HIWIN. This increased the forces of the R&D department: thanks team, the factory also produced software able to read design drawings and connect to the machine for the production of the pieces, making SOCO a challenging competitor in the laser cutting industry.

Frank Lin, who is a non-sole proprietorship, admits that although the company's gross profit margin has broken through 30% every year, its net profit performance has not been higher than that of its peers due to higher employee benefits and R&D costs, the interests of shareholders including himself are sacrificed.

How does Lin persuade the shareholders to support his reform?

"I'm relatively strong, but I haven't let the company lose money in 41 years. Shareholders believe me."

Walking into the Taichung headquarters of SOCO Machinery, you can see the results of this transformation. Furniture manufacturers -- including Ikea's supply chain -- can buy a laser production line and will not need sets of molds anymore. Thanks to the new technology adopted, the production can be completed with one click. The design drawings are read by the software of the machine, which can process the material in full automation. Fully automated robots handle the materials on the production line. Manpower can be reduced from 5-6 people, down to only one person; the production time can be shortened from 3 months to a week.

When SOCO entered the furniture and sports equipment industry three years ago, it relied on a new production model to save money and labor for customers abroad. SOCO's furniture and sports equipment total revenue accounted for less than 10% at the beginning and quickly increased to 30%.

At the same time, the gross profit margin of the new production line also grew from 5% to 10% higher than the previous sales, to make up for the revenue and profit gap caused by the loss of automotive orders.

Looking forward to the future, the machinery industry has entered a new era of a strong New Taiwanese Dollar. Even Frank Lin admits that the impact of foreign exchange losses on profits has become a new source of pressure on business operations, and he must be prepared: "This year, we will spend more than 1 billion NTD in business revenue for half a year: "We are willing to endure low net profit for several years. We also built a new laser application base in Nangang Industrial Zone, Nantou. Regardless of the cost, we will get more orders with high margins in the future".

Xu Wentong, secretary-general of the Taiwan Association of Machinery Industry, believes that Taiwan's machinery industry can no longer expect meager profits from the depreciation of the New Taiwanese Dollar. It must have the ability to use unique technology, like SOCO Machinery, enter niche markets and create higher added value.

Source From : https://www.businessweekly.com.tw/magazine/Article_mag_page.aspx?id=7002541